PROJECT:

Lolly Wolly Doodle ERP

Extensive End-To-End Enterprise Resource Planning System

CONTEXT:

Lolly Wolly Doodle specialized in custom, made-to-order, women's & children's apparel.

The ERP system was the foundation on which every aspect of the company was managed and allowed to scale. "Off-the-shelf" ERP software systems had not been a good fit for the company due to many unique hurdles in its manufactoring process. LWD decided to undertake the challenge of creating a custom ERP system from scratch.

It would serve as a massive paradigm shift for the company

MY ROLES:

- Part of a collaborative team that established end-to-end manufactoring and warehouse standard procedures

- Liaison between engineers and company stakeholders

- UX/UI Design

- QA & Usability Testing

- Oversaw all release roll outs and provided ongoing training to 50+ employees

THE PROBLEM

LWD rocketed to success in a short time. It went from a garage side hustle to a multi-million dollar business in a few short years. The first manufactoring and fulfillment processes were manual pencil & paper with many obvious flaws. (Human error, no real-time tracking, no reporting, etc.) It was slow, painstaking, and limiting. LWD needed an ERP system to survive and scale. "Off-the-shelf" systems proved to not be the best fit for the unique manufactoring processes.

SOLUTION & GOALS

- Using a completely in-house team, Build an end-to-end ERP system from scratch that is specificly tailored to the needs of LWD

- Define scope and requirements for an initial minimum viable product

- Establish scalable manufactoring operations to work within the initial ERP roll out and subsequent releases

- Institute new employee roles and processes around the ongoing ERP tech maintenance, updates, projects, and training

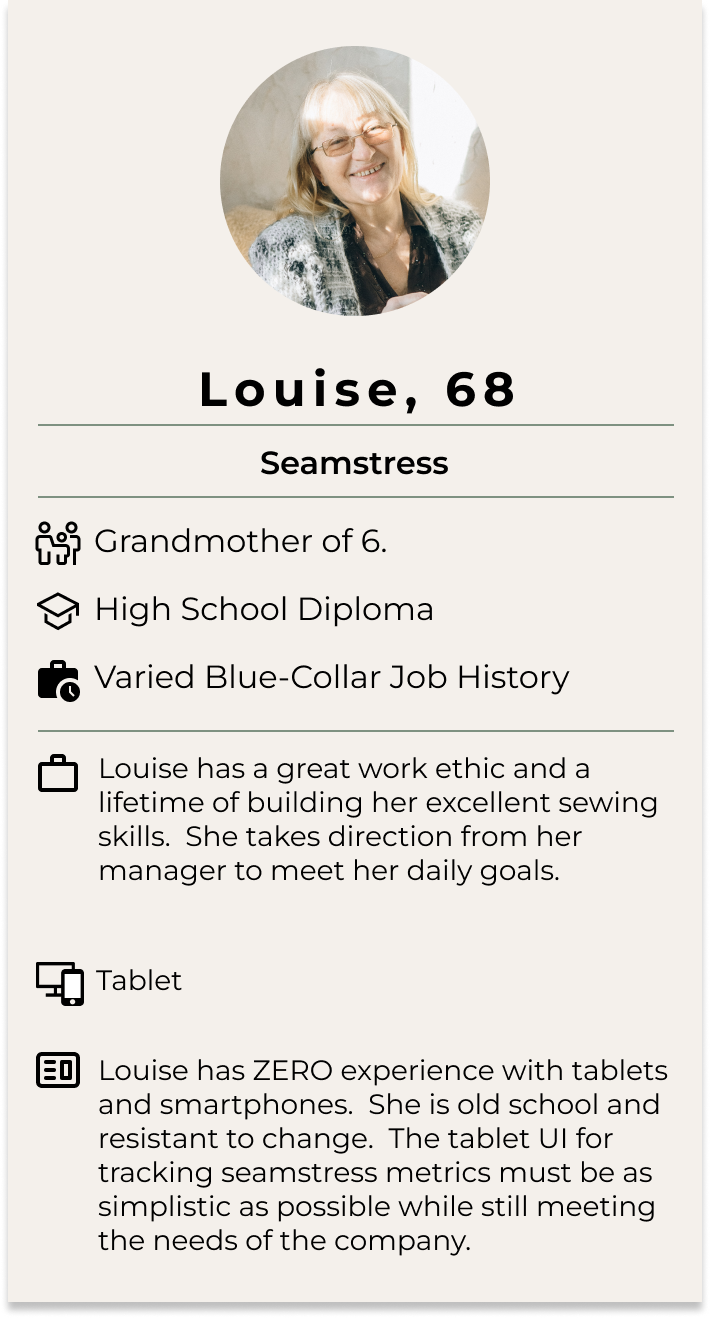

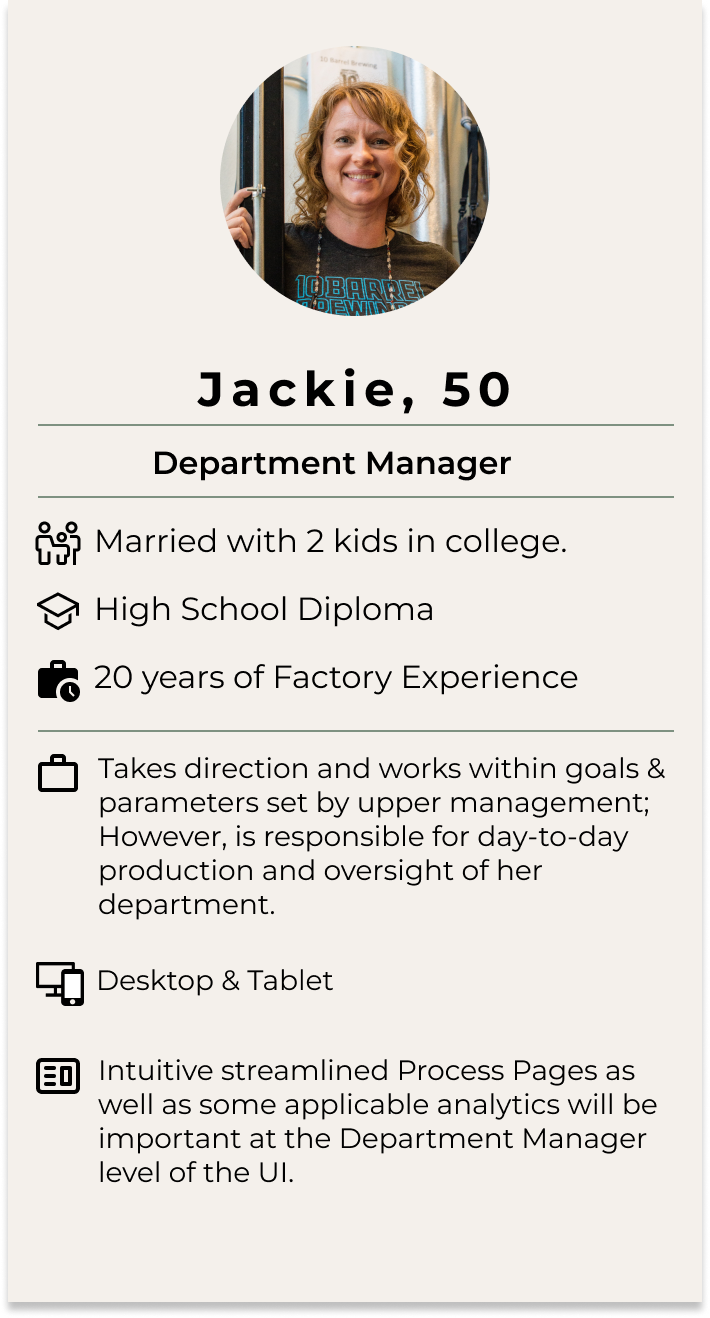

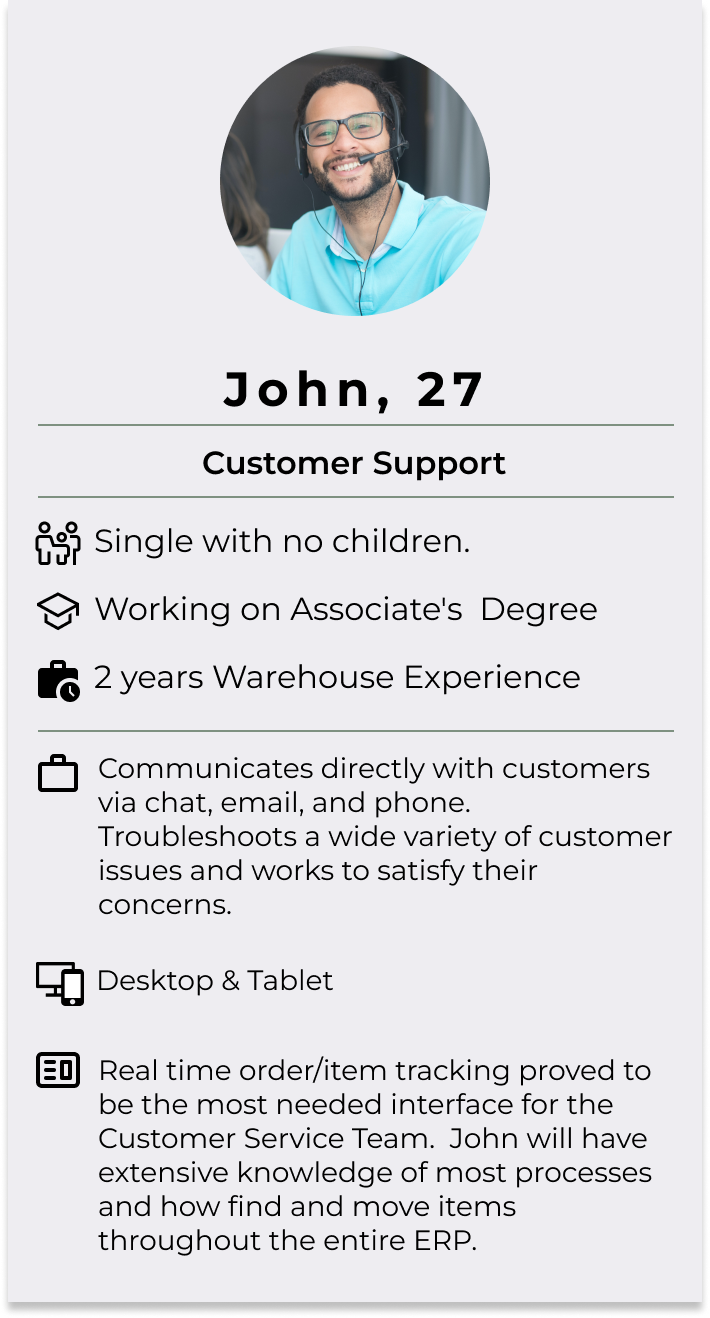

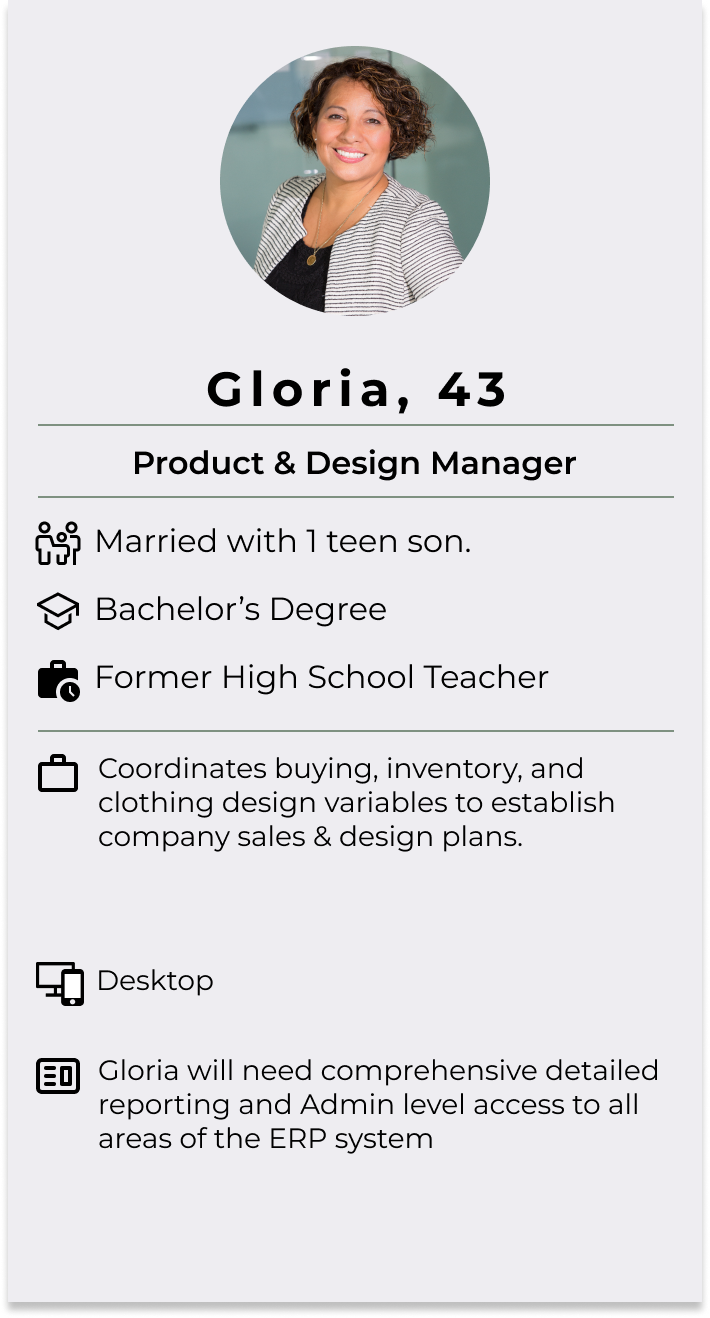

USERS:

Every employee in the company used this system daily. Each user journey and specific system function determined the persona it was designed for.

Supply Chain Personas

Office Personas

Version 1 - Minimum Viable Product

Goals of v1:

- ERP Team Members Immerse ourselves in the daily needs of each department to create a highly collaborative hands-on process

- Define Main Product Item Types & establish their manufactoring flows and processes

- Define SKU naming conventions & Start SKU creation process for all items

- Design the basic look, feel, & functionality of the ERP System

- Physically Set up Factory & Warehouse departments to efficiently execute item flows

- Define New Management roles and their necessary ERP interfaces

- Account for the main process exceptions and establish both physical and ERP user journeys for when they arise

- Train employees on applicable software and hardware while assessing their user feedback

- Create a variety of reporting dashboards

- Work closely with employees and oversee roll of out of v1

- Design everything with scalability in mind, Immediately beginning work on v2

COO leads our very first of many brainstorming sessions

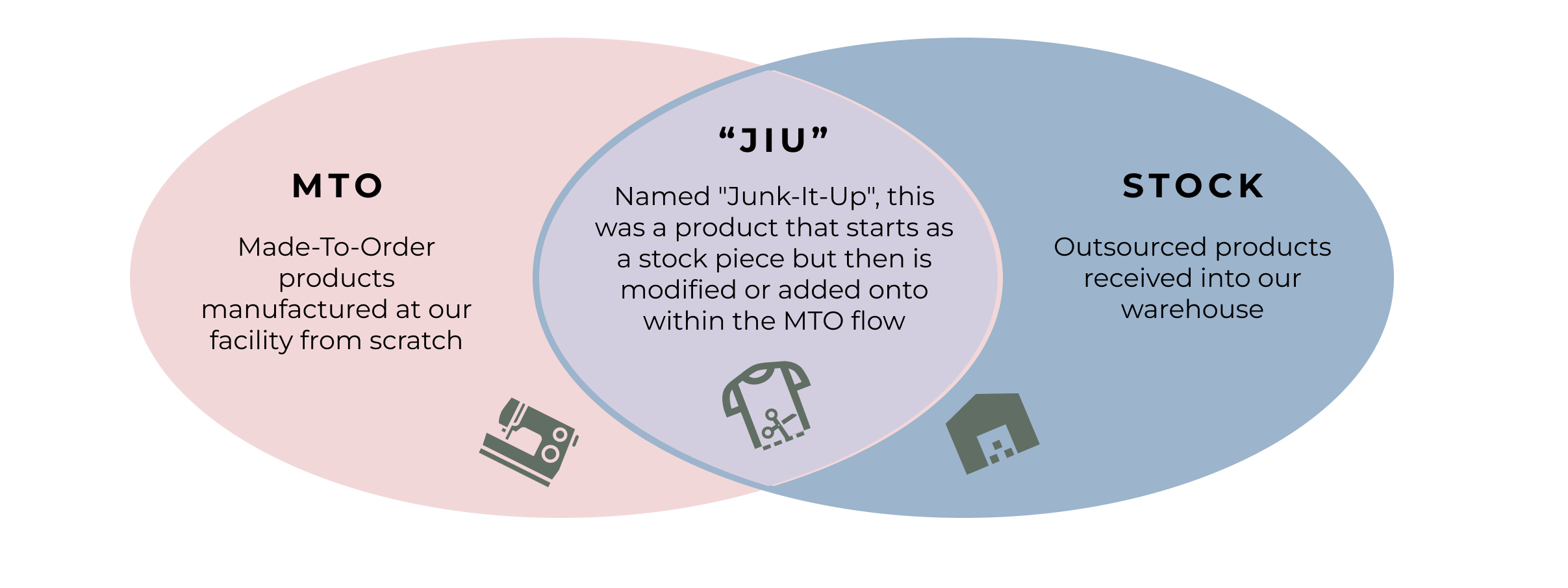

Define Main v1 Item Types:

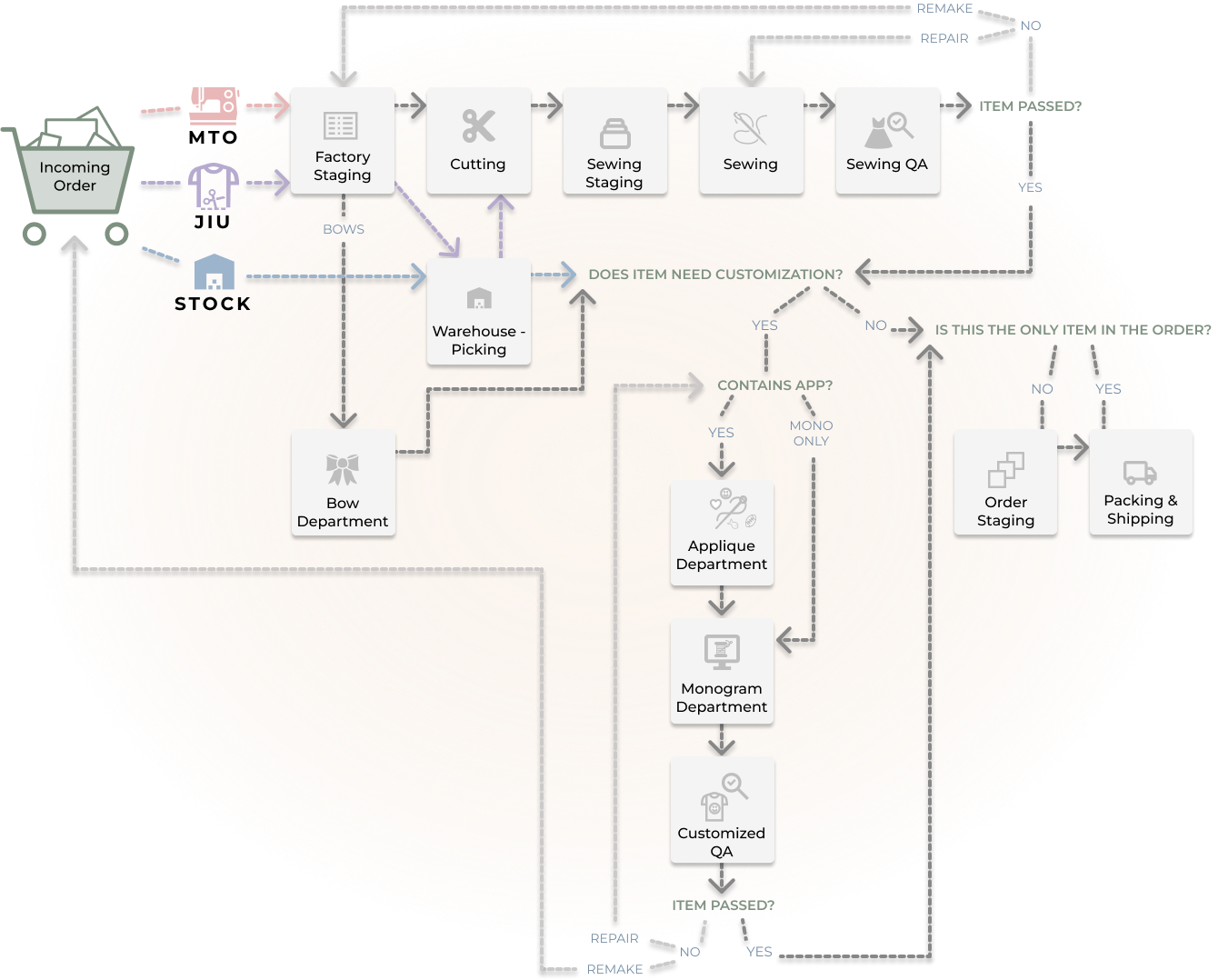

For v1, a customer's order could consist of any combination of the following item types:

Each item type had unique manufactoring flows.

Each item type had the option for additional customization processes.

All item flows converge at the end of the system to fulfill complete orders.

Define Basic v1 Order Flows:

Required v1 UX Interfaces & Journeys:

Based on the v1 Goals, Main Item Types, & Order Flows, the following list outlines the scope of the UX interfaces & journeys required. From brainstorming to release, the minimum viable product took about 1 year.

*Wireframes of noted user experiences included below

| DEPARTMENT | UX | PERMISSION

LEVEL |

DEVICE/

INPUT |

HARDCOPY

UIs |

|

|---|---|---|---|---|---|

| Design | SKU Creation | Manager | |||

| Design Library & Archive | Manager | ||||

| Fabric Inventory | Manager | ||||

| Factory | Factory Staging | Manager | |||

| Cutting Staging | Manager | Batch Summary Print Out | |||

| Cutting | Manager | ||||

| view LoFi | Sewing Staging* | Manager | |||

| view LoFi | Sewing* | Manager | |||

| view HiFi & Prototype | Sewer Station* | Worker | |||

| Factory QA - Dashboard | Manager | Barcode & Item Info Tags | |||

| Factory QA - QA Station | Worker |

|

|||

| Bow Department | Worker | ||||

| Warehouse | Warehouse Staging | Manager | |||

| Warehouse Picking - Dashboard | Manager | ||||

| Warehouse Picking | Worker |

|

|||

| Order Staging - Dashboard | Manager | ||||

| Order Staging - Staging Process | Worker |

|

|||

| Order Staging - Pick & Pack Process | Worker |

|

|||

| Shipping | Worker | Packing List | |||

| Customization | Applique Staging | Manager | |||

| Applique - Dashboard | Manager | Barcode & Item Info Tags | |||

| Applique Station | Worker |

|

|||

| Monogram Staging | Manager | ||||

| Monogram - Dashboard | Manager | Barcode & Item Info Tags | |||

| Monogram Station | Worker |

|

|||

| Warehouse QA - Dashboard | Manager | ||||

| Warehouse QA - QA Station | Worker |

|

|||

| Misc | Activity/Audit Log Tracking | Manager | |||

| Log Exception Flows | Manager | ||||

| Check Status | Worker |

|

|||

| Admin | Reports | Admin/Manager | |||

| User Management | Admin | ||||

| Customer Support | Customer Management | Worker | |||

| Ability to add Item Notes/Alerts | Worker | ||||

| Order/Item Management | Worker |

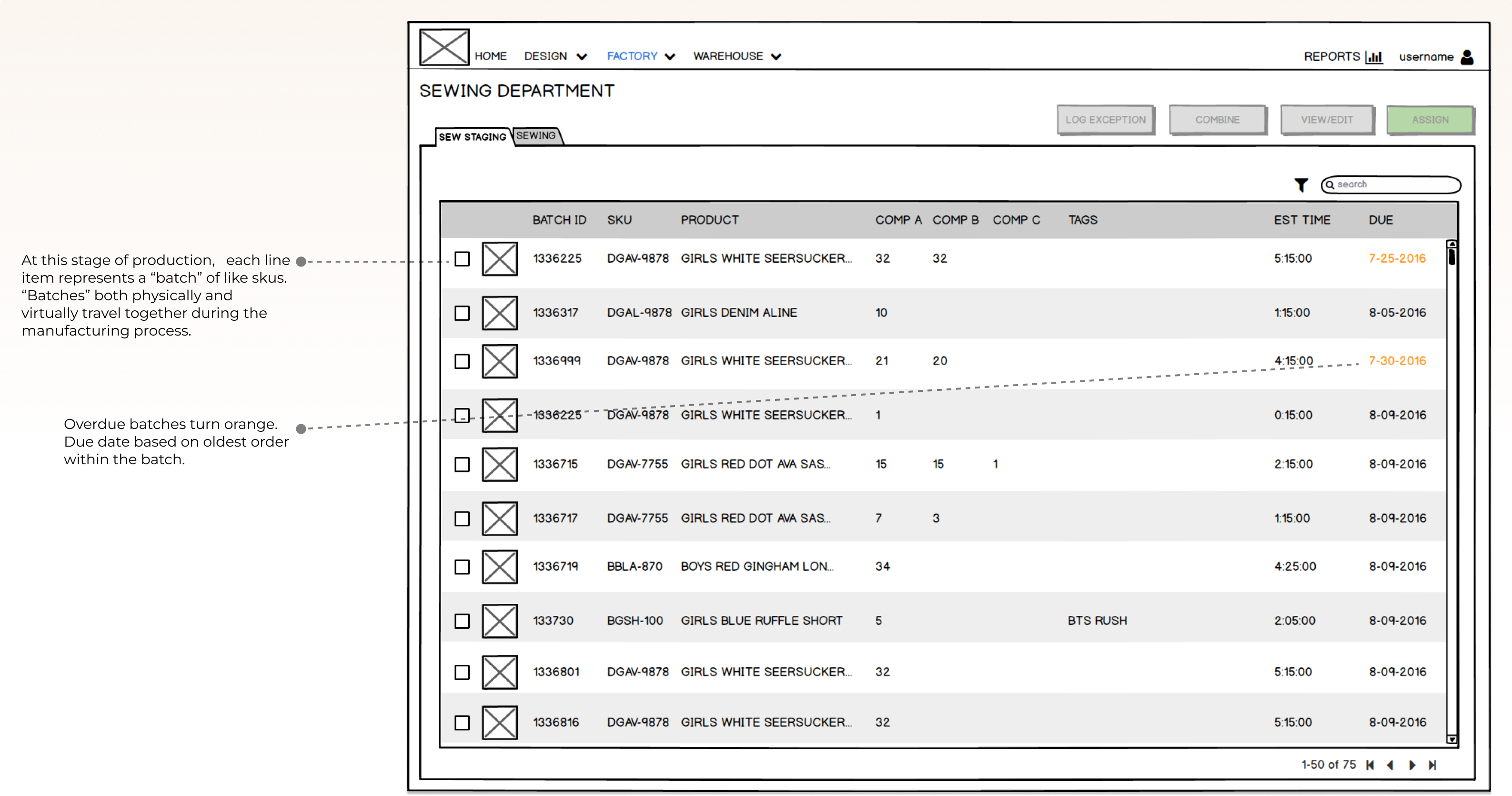

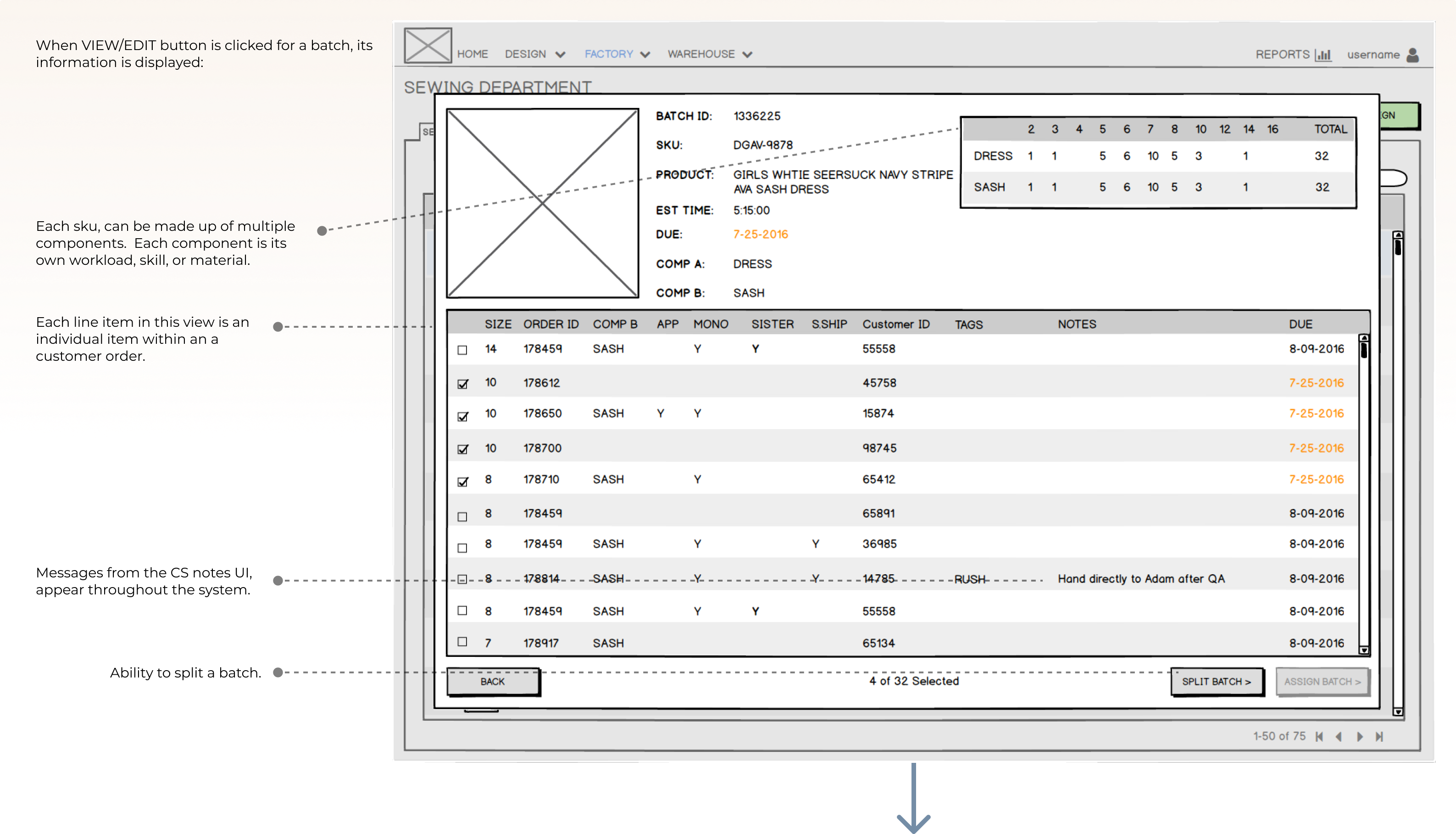

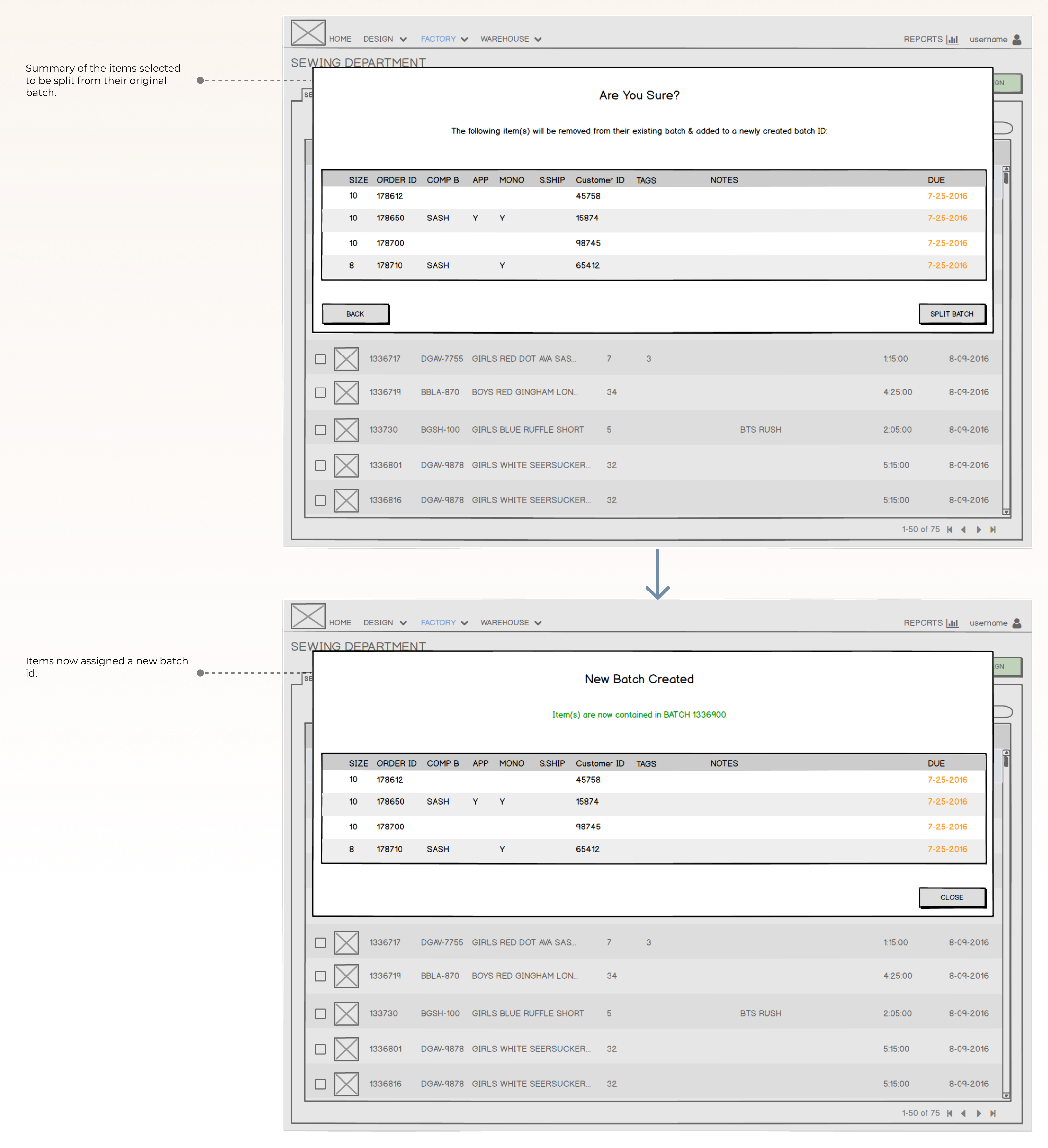

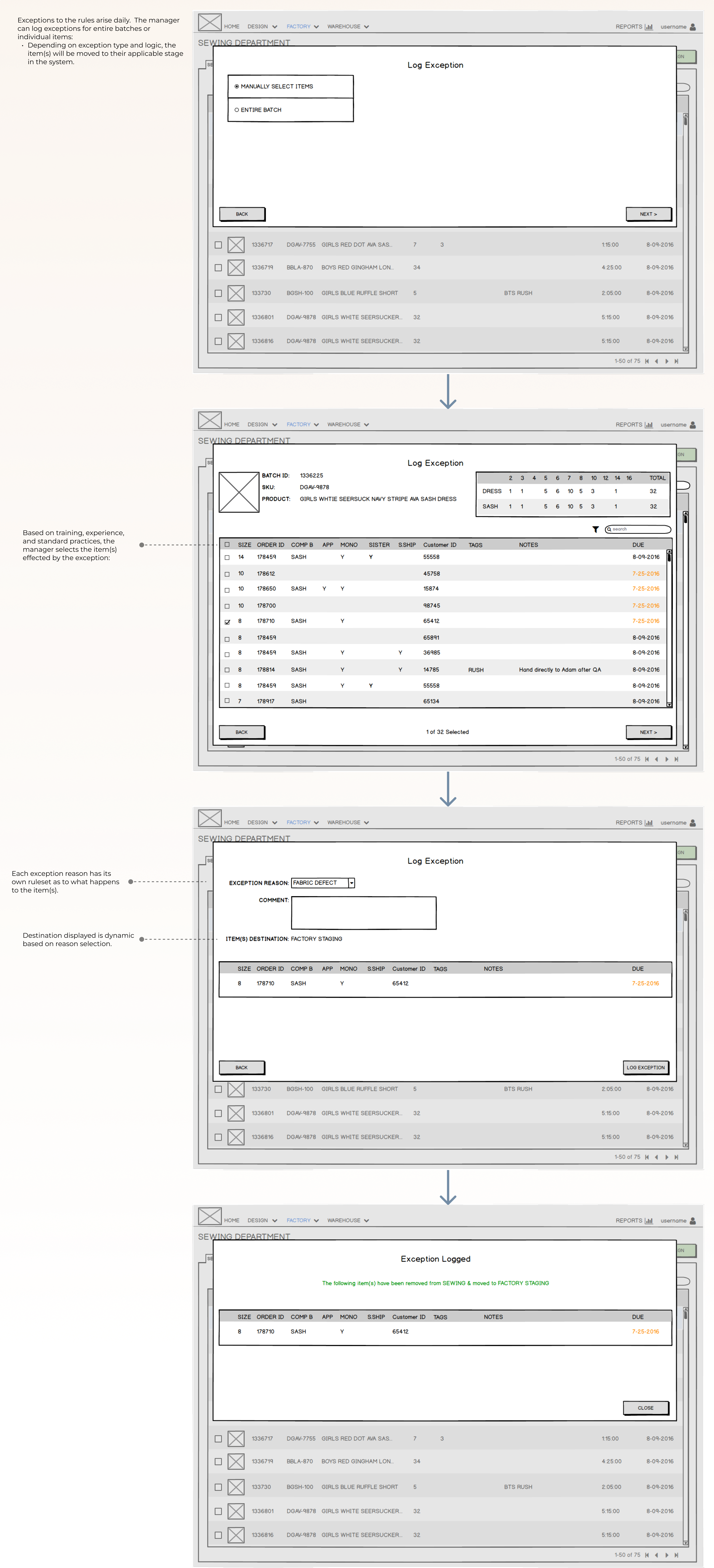

Sewing Department UI Examples:

Sewing Manager LoFi Wireframes:

- Serves as a Snapshot of the Sewing Department's Work Load

- Provides Management with all necessary production functions such as assigning work, logging exceptions, and moving batches of work along to the next steps

- The fundamental design of the manufacturing managers' screens was a traditional table displaying all necessary information with the ability to filter, search, and perform actions on the line items.

SEW STAGING

SEW STAGING >

VIEW/EDIT

SEW STAGING >

VIEW/EDIT >

SPLIT BATCH

SEW STAGING >

LOG EXCEPTION

SEW STAGING >

ASSIGN

SEWING

Sewer Tablet UX Prototype & HiFi Wireframes:

- Each sewer had an android tablet at their workstation

- This UX is designed for quick, intuitive, & simple actions

-

Many Sewers had little to no experience with tech devices. It was crucial to observe their needs and feedback for the best possible experience.

Intentional Design Choices:

- Large target areas on buttons and CTAs

- Color coded start/stop buttons

- Color coded task statuses

- Large images

- Simplied and edited down batch information

REFLECTIONS:

The ERP system continually evolved and adapted to the company's changing needs. Our goal of scalability was a success, as there was never a large-scale refactor or redesign required in the subsequent years.

After the foundation was laid by v1, additional sprints and larger releases were streamlined.